Blasting Abrasives for Surface Preparation

Introduction to Blasting Abrasives

Blasting abrasives play a pivotal role in numerous industrial applications that require the cleaning, roughening, or shaping of substrates. Their strategic use ensures that surfaces are adequately conditioned to receive coatings, overlays, or other treatments. This article provides a comprehensive technical overview of blasting abrasives, exploring their classifications, properties, and applications.

Let’s first understand what exactly are blasting abrasives.

What are Blasting Abrasives?

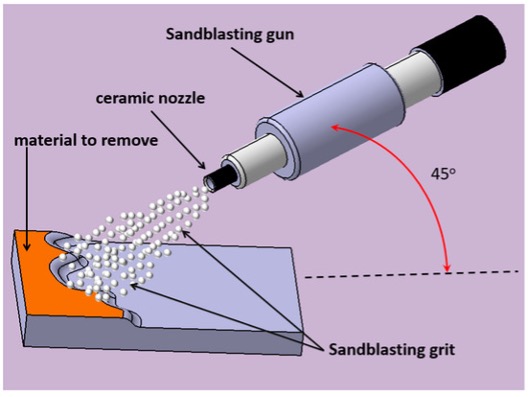

Blasting abrasives are granular or particulate materials used to clean, roughen, or shape surfaces through mechanical impact in a process commonly referred to as abrasive blasting. In industrial practice, abrasive blasting is indispensable for preparing surfaces before the application of protective coatings, removing corrosion products, and achieving specific surface profiles conducive to coating adhesion.

The selection of an appropriate blasting abrasive is important, as it directly influences surface cleanliness, profile, and the overall performance of subsequent coatings. A poorly chosen abrasive can lead to substrate damage, inadequate surface roughness, excessive embedment, or contamination—all of which compromise the protective performance of coatings or further surface treatments. Consequently, engineers and maintenance professionals must understand the characteristics and suitability of different abrasives for various substrates and service environments.

Blasting operations are typically governed by international standards such as SSPC (Society for Protective Coatings), NACE (now AMPP), ISO 8501, and ISO 11124, which define cleanliness levels, surface profile requirements, and permissible abrasive materials. Additionally, safety regulations from agencies such as OSHA and NIOSH establish permissible exposure limits (PEL) for dust and toxic metals generated during abrasive blasting.

We have seen a basic overview of blasting abrasives. Next, let’s delve deep into their role in surface preparation.

Abrasives are fundamental to surface preparation processes, and serve as the primary agents responsible for altering the physical topography of a substrate. Their role extends beyond mere cleaning; they enable mechanical bonding between a surface and the applied coating by creating the necessary surface roughness or anchor profile. The type, size, hardness, and shape of abrasive particles determine the extent of material removal, cleanliness level, and surface profile achieved. Properly prepared surfaces contribute to increased coating adhesion, reduced risk of premature coating failure, and enhanced corrosion resistance.

Surface preparation using abrasives also facilitates the removal of rust, mill scale, old coatings, and contaminants such as salts and oils, all of which can inhibit coating performance. Depending on the abrasive material and blasting parameters, processes can range from aggressive profiling for structural steel to gentle cleaning for precision components and delicate materials. Industry standards, such as those from SSPC, ISO, and AMPP, emphasize the importance of achieving defined surface conditions prior to coating application. This shows the abrasive’s pivotal role in achieving long-term protective performance and structural integrity.

Blasting abrasives are granular or particulate materials used to clean, roughen, or shape surfaces through mechanical impact in a process commonly referred to as abrasive blasting. In industrial practice, abrasive blasting is indispensable for preparing surfaces before the application of protective coatings, removing corrosion products, and achieving specific surface profiles conducive to coating adhesion.

Next, let’s look into the classification of abrasives.

Classification of Blasting Abrasives

Blasting abrasives are classified by origin, composition, and reusability—natural vs. synthetic, metallic vs. non-metallic, and expendable vs. recyclable. These distinctions help engineers match abrasives to substrate sensitivity, cleaning intensity, and cost-effectiveness in varied industrial environments.

Natural vs. Synthetic Abrasives

- Natural Abrasives: These include garnet, olivine, pumice, and walnut shells. They are sourced directly from natural deposits and processed to achieve the desired particle size and shape.

- Synthetic Abrasives: These are manufactured through controlled industrial processes. Common examples include aluminum oxide, silicon carbide, and plastic media. Synthetic abrasives often offer greater consistency in hardness, shape, and performance.

Metallic vs. Non-Metallic Abrasives

- Metallic Abrasives: Steel grit, steel shot, and stainless steel shot fall under this category. They are typically recyclable and used in closed-loop blasting systems due to their durability and density.

- Non-Metallic Abrasives: These include both natural and synthetic materials such as garnet, glass beads, slag, and ceramic media. Non-metallic abrasives are often expendable and suited for one-time use.

Expendable vs. Recyclable Abrasives

- Expendable Abrasives: Designed for single-use applications. Common examples include copper slag, coal slag, and staurolite. These are typically used in open blasting environments.

- Recyclable Abrasives: Capable of multiple reuses without significant degradation. Steel grit and aluminum oxide belong to this category. These are more economical in controlled blasting setups such as blast cabinets and rooms.

Common Types of Abrasives

The following sections examine the most widely used blasting abrasives in industrial surface preparation, emphasizing their technical attributes and performance characteristics.

Garnet

- Chemical Composition: Fe₃Al₂(SiO₄)₃ (Almandine)

- Hardness:5–7.5 (Mohs)

- Density:9–4.2 g/cm³

- Particle Shape: Sub-angular to angular

- Properties: Garnet is a natural, non-metallic abrasive with low free silica content (<1%), making it safer for operators. Its high hardness and angularity provide excellent cutting action and efficient surface profiling. It is suitable for use on ferrous and non-ferrous substrates and supports recyclable use in suitable systems.

Advantages: Garnet offers a low free silica content, making it safer for operators and environmentally compliant. Its sharp, angular grains provide efficient cleaning and profiling for both ferrous and non-ferrous metals. Suitable for both wet and dry blasting, it presents minimal risk of substrate contamination.

Disadvantages: Garnet has moderate recyclability, which limits its cost efficiency over extended use. It can also generate more dust compared to metallic abrasives, requiring moderate dust control measures.

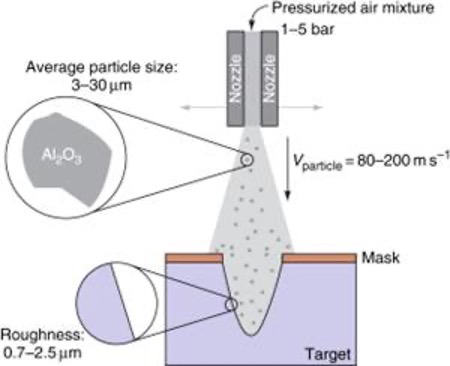

Aluminum Oxide

- Chemical Composition: Al₂O₃

- Hardness: 9 (Mohs)

- Density:9–4.1 g/cm³

- Particle Shape: Angular

- Properties: A highly durable synthetic abrasive, aluminum oxide is ideal for aggressive cleaning and roughening. Its high friability allows it to fracture into sharp edges, maintaining consistent cutting efficiency. Suitable for both wet and dry blasting and effective on hard metals and ceramics.

Advantages: Known for its extreme hardness and friability, aluminum oxide is effective for aggressive cleaning and surface preparation. It offers high recyclability and consistent performance across multiple cycles, making it ideal for controlled environments.

Disadvantages: The high cost of aluminum oxide can be a barrier for smaller operations. Additionally, it requires appropriate containment and dust extraction systems to manage particulate emissions.

Steel Grit and Steel Shot

- Chemical Composition: Cast steel (carbon or stainless)

- Hardness: Grit: 40–65 HRC; Shot: 40–50 HRC

- Density: ~7.4 g/cm³

- Particle Shape: Grit: Angular; Shot: Spherical

- Properties: Steel abrasives are robust and recyclable up to 1000 times in controlled environments. Steel grit produces a sharp profile suitable for coating adhesion, while steel shot is used for peening and surface smoothing. They generate minimal dust and are highly efficient in closed-loop operations.

Advantages: Steel abrasives are extremely durable and cost-effective in long-term operations due to their very high recyclability. Steel grit provides a sharp angular profile ideal for coating adhesion, while steel shot is excellent for peeningand smoothing.

Disadvantages: The initial investment is high due to equipment requirements. Furthermore, these abrasives can cause ferrous contamination on non-ferrous substrates and are unsuitable for open-field operations.

Glass Beads

- Chemical Composition: Soda-lime glass (SiO₂-based)

- Hardness: 5–6 (Mohs)

- Density:4–2.6 g/cm³

- Particle Shape: Spherical

- Properties: Glass beads are non-aggressive and used primarily for cleaning, deburring, and finishing applications. They provide a peened, satin-like finish with minimal surface removal. Ideal for aerospace and medical components where dimensional accuracy is critical.

Advantages: Glass beads are ideal for cleaning delicate surfaces without removing substrate material. They produce a smooth, satin finish and are environmentally inert with low silica content.

Disadvantages: They offer limited surface profile generation and may fracture under high pressures, reducing their effective service life.

Silicon Carbide

- Chemical Composition: SiC

- Hardness: 9-9.5 (Mohs)

- Density: ~3.2 g/cm³

- Particle Shape: Angular

- Properties: Silicon carbide is one of the hardest known abrasives, making it ideal for rapid material removal and hard substrate cleaning. It is thermally stable and chemically inert, suitable for use on titanium, stainless steel, and ceramics. Its high cost limits its use to specialized applications.

Advantages: One of the hardest materials available, silicon carbide rapidly removes tough coatings and corrosion. It is chemically inert, produces minimal dust, and is ideal for refractory metals and ceramics.

Disadvantages: Its high cost makes it suitable only for specialized applications. The sharp fragments require stringent PPE usage and can damage softer substrates.

Copper Slag

- Chemical Composition: Complex silicates containing iron, silicon, and aluminum

- Hardness: 6–7 (Mohs)

- Density:8–3.9 g/cm³

- Particle Shape: Angular

- Properties: A byproduct of copper smelting, copper slag is an expendable abrasive with good cutting performance. It is widely used in shipyards and steel structures. However, variability in composition and the presence of heavy metals require compliance with environmental and occupational safety guidelines.

Advantages: Copper slag is a cost-effective abrasive with good cutting ability. It is widely available and particularly effective on steel structures and ship hulls.

Disadvantages: Its composition can include heavy metals, requiring environmental controls and proper disposal. It has low reusability and moderate dust generation.

Coal Slag

- Chemical Composition: Silico-aluminous material

- Hardness: 6–7 (Mohs)

- Density:4–2.8 g/cm³

- Particle Shape: Angular

- Properties: Another expendable abrasive derived from coal combustion byproducts. Coal slag is effective in removing rust and coatings but is known to produce higher dust levels. It contains trace elements like arsenic and beryllium, necessitating strict adherence to OSHA regulations.

Advantages: An inexpensive abrasive that is readily available and effective for removing paint, rust, and scale. It is frequently used in structural steel and bridge maintenance.

Disadvantages: It generates significant dust and may contain toxic elements such as arsenic or beryllium. It is non-recyclable and must be handled with full safety precautions.

Walnut Shells

- Chemical Composition: Lignocellulosic material

- Hardness:5–3.5 (Mohs)

- Density: 1-1.4 g/cm³

- Particle Shape: Angular to sub-angular

- Properties: A biodegradable, soft abrasive suitable for delicate surfaces such as wood, aluminum, and composites. It is used in aerospace and restoration work, providing cleaning without dimensional alteration or substrate damage.

Advantages: Ideal for cleaning soft substrates and removing surface contaminants without damaging base materials. Biodegradable and non-sparking, walnut shells are suited for aerospace and restoration work.

Disadvantages: Limited abrasiveness and short operational life make them less suitable for heavy-duty applications. Potential allergenicity also requires operator awareness.

Plastic Media

- Chemical Composition: Urea, polyester, acrylic, or melamine resins

- Hardness: 3–4 (Mohs)

- Density: ~1.5 g/cm³

- Particle Shape: Angular

- Properties: Plastic abrasives are non-aggressive and commonly used for deflashing, deburring, and paint stripping on sensitive substrates. Ideal for applications requiring minimal surface roughness and dimensional integrity.

Advantages: Plastic media is well-suited for paint stripping and cleaning of sensitive materials such as composites and plastics. It offers high recyclability and produces minimal dust.

Disadvantages: Not suitable for corrosion or heavy coating removal. The high initial cost and limited surface profiling capability are notable constraints.

Staurolite

- Chemical Composition: (Fe,Mg)₂Al₉Si₄O₂₃(OH)

- Hardness: 7–7.5 (Mohs)

- Density: ~3.7 g/cm³

- Particle Shape: Angular

- Properties: Staurolite is a naturally occurring mineral abrasive with low free silica content. It offers a good balance between cutting efficiency and surface finish, suitable for both structural steel and concrete surfaces.

Advantages: Staurolite provides a balance of cutting efficiency and safety with relatively low silica content. It is effective on steel and concrete and produces a good surface profile.

Disadvantages: Its availability can be limited in some regions. It has low to moderate reusability and generates a moderate level of dust, requiring standard protective measures.

Now let’s move on to the selection criteria for Abrasive Blasting Media

Selection Criteria for Abrasive Blasting Media

Selecting an abrasive blasting medium involves multiple technical and regulatory considerations. The optimal choice ensures maximum coating performance, process efficiency, and compliance with environmental and occupational safety standards.

1. Substrate Material Compatibility

Different substrates require different abrasives to prevent distortion, contamination, or damage:

- Carbon Steel: Most aggressive abrasives such as steel grit, copper slag, or aluminum oxide are suitable.

- Stainless Steel/Non-Ferrous Metals: Non-ferrous abrasives like garnet, glass beads, or plastic media are preferred to avoid galvanic corrosion.

- Aluminum and Soft Alloys: Require low-hardness abrasives such as plastic media, walnut shells, or glass beads.

- Composite Materials and Plastics: Soft abrasives like plastic and walnut shell are critical to prevent substrate erosion.

2. Desired Surface Profile and Anchor Pattern

Coating adhesion is influenced by the surface profile (peak-to-valley height):

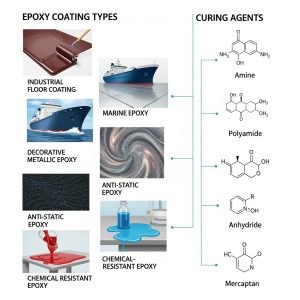

- High-Build Coatings (e.g., epoxy, polyurethane): Require deeper profiles (75–125 µm), achievable with steel grit, aluminum oxide, or silicon carbide.

- Thin-Film Coatings (e.g., zinc-rich primers): Demand finer profiles (25–50 µm), achievable using glass beads or garnet.

Surface profile selection should align with coating manufacturer’s recommendations and standards such as SSPC-SP 5 to SP 10 and ISO 8503.

3. Coating System Requirements

The following considerations help align abrasive selection with the end-use coating system:

- Thermal Spray Applications: Need rough profiles for mechanical interlock; steel grit or alumina preferred.

- Powder Coating: Typically requires low-profile finishes; glass bead or plastic media ideal.

- NACE/AMPP-Certified Coating Protocols: May specify abrasive types, profiles, and cleanliness levels (e.g., white metal or near-white blast per SSPC-SP 5/10).

4. Cost-Effectiveness and Media Consumption Rate

While expendable abrasives offer low upfront cost, recyclable media reduce long-term expenses:

- High-Reusability (e.g., steel grit, aluminum oxide): Require initial capital for blast cabinets or recovery systems but reduce cost per cycle.

- Low-Cost, Single-Use Media (e.g., coal slag, copper slag): Suitable for one-time jobs or open-field work but increase waste generation and disposal costs.

Total cost of ownership includes not just abrasive purchase price but also collection, reprocessing, and disposal.

5. Reusability and Waste Disposal Concerns

Environmental regulations and operational sustainability necessitate efficient use and minimal waste:

- Steel Media: Can be reused hundreds of times; minimal waste; ideal for controlled environments.

- Slag Abrasives: Typically single-use; require disposal as industrial waste or potentially hazardous material depending on composition.

- Organic Media (e.g., walnut shells): Biodegradable but short-lived; require dust control to avoid allergen exposure.

Waste classification should comply with RCRA and local hazardous waste rules. Documentation of chemical content (e.g., TCLP testing) may be required.

6. Environmental and Worker Safety Regulations

Compliance with safety and environmental standards is non-negotiable in abrasive blasting operations:

- Dust Control: Abrasives should minimize airborne particulate matter. Steel media and plastic beads are preferable in enclosed environments. High-dust abrasives like coal slag need enhanced ventilation.

- Silica Exposure: Crystalline silica content must be below regulatory thresholds. OSHA mandates a PEL of 50 µg/m³ for respirable crystalline silica, averaged over 8 hours.

- Heavy Metals & Toxins: Abrasives containing arsenic, lead, or beryllium (often found in slags) require hazard communication protocols and respiratory protection per OSHA HAZCOM and NIOSH

- Noise and PPE: High-pressure blasting requires hearing protection, respirators, and full-body suits. Operator safety training should align with OSHA 1910.94 (Ventilation) and 134 (Respiratory Protection).

Industrial Applications and Uses of Abrasives

Abrasive blasting serves a broad range of industrial purposes beyond general cleaning, with specific abrasive types aligning to unique operational goals and material requirements.

Coating Preparation

Prior to applying protective coatings, creating an optimal surface profile is essential for mechanical adhesion. Steel grit, aluminum oxide, and garnet are widely employed in industries such as shipbuilding, bridge maintenance, and steel fabrication to establish anchor profiles ranging from 50 to 150 µm. Standards like SSPC-SP 10 and ISO 8501-1 guide surface cleanliness levels required for effective coating adhesion.

Rust and Mill Scale Removal

Heavily corroded or mill-scaled steel surfaces in the oil & gas, marine, and infrastructure sectors require aggressive abrasives such as copper slag, coal slag, or steel grit. These abrasives efficiently remove corrosion products, leaving behind a clean surface that enhances the lifespan of anti-corrosive coatings.

Industrial Equipment and Component Cleaning

Routine maintenance of valves, turbines, heat exchangers, and pumps often necessitates abrasive blasting to remove fouling, carbon buildup, and scale. Aluminum oxide and steel shot are preferred for their cutting efficiency and reusability in such applications.

Peening and Surface Strengthening

Shot peening is a controlled process used to improve fatigue strength and stress resistance in components such as aerospace gears, springs, and automotive parts. Steel shot or conditioned cut wire media are used to impart compressive stresses, thereby delaying crack initiation and propagation.

Delicate Surface Cleaning and Restoration

Glass beads, walnut shells, and plastic media are suitable for applications requiring minimal surface impact. Restoration of historical artifacts, paint stripping from aircraft skins, and cleaning of soft substrates like wood or composites benefit from these softer abrasives.

Aerospace and Precision Industries

In aerospace manufacturing and MRO (maintenance, repair, and overhaul), surface cleanliness without dimensional alteration is critical. Non-metallic abrasives like glass beads, plastic media, and fine garnet are commonly used for deflashing, depainting, and component preparation.

Concrete Surface Profiling

In civil engineering, abrasive blasting is used to roughen concrete surfaces to enhance the bond of overlays, coatings, or waterproof membranes. Angular abrasives such as staurolite and steel grit are favored for their ability to expose aggregate and provide mechanical keying.

These diverse applications underscore the necessity of matching abrasive type to operational need, substrate sensitivity, and end-use requirements. The correct pairing leads to increased component longevity, improved coating performance, and reduced rework costs.

Conclusion

Blasting abrasives form the foundation of effective surface preparation, influencing not only the immediate cleaning and profiling results but also the long-term durability of coatings and structural integrity of components. Selecting the optimal abrasive requires a nuanced understanding of substrate properties, desired surface profile, blasting environment, and operational economics.

Professionals involved in surface engineering must consider both the physical characteristics of abrasives—such as hardness, shape, and density—and regulatory factors like permissible exposure limits, waste disposal requirements, and environmental impact. By aligning abrasive selection with technical specifications and safety standards, industries can achieve superior coating performance, operational efficiency, and regulatory compliance.

Adherence to industry standards and guidelines from NIOSH ensures safe, efficient, and environmentally responsible blasting operations. As materials technology and environmental regulations evolve, so too must the understanding and application of blasting abrasives in modern industrial contexts.

Blog Prepared by:

R. Venkatesan

Protective Coating Specialist

Senior Training Instructor for FROSIO / ICorr

+91-9176618930 / info@htscoatings.in / info@frosiotraining.com