Introduction

Marine protective coatings are specialized coating systems designed to protect vessels and offshore structures from the harsh conditions of the marine environment. These coatings play an important role in preserving the structural integrity, safety, and operational lifespan of maritime assets such as ships, oil rigs, and port infrastructure.

In salt-laden marine environments, steel and other substrates are constantly exposed to various threats such as corrosion, biofouling, ultraviolet radiation, mechanical abrasion, and chemical attack. Without adequate protection, these structures deteriorate quickly, leading to high maintenance costs, operational downtime, and even structural failure.

Marine coatings provide a barrier that prevents or slows down the interaction between corrosive agents and the substrate. In addition to corrosion resistance, these coatings can reduce drag on ship hulls, thereby improving fuel efficiency and lowering emissions

Before we delve deep into the types of marine protective coatings check out our article, Protective Coatings – FROSIOto get in depth knowledge about protective coatings.

Types of Marine Protective Coatings

Marine coatings can be broadly classified into several categories based on their function, composition, and application area. The primary types include anti-corrosive coatings, antifouling paints, foul-release coatings, and topcoats. These can be formulated as solvent-borne or waterborne systems, depending on environmental and application requirements.

Anti-Corrosive Coatings

Corrosion is the primary enemy of steel structures exposed to seawater, and anti-corrosion coatings form the first line of defense. These coatings are designed to interrupt electrochemical reactions that would otherwise cause rapid degradation of the metal. Anti-corrosive systems typically begin with a primer, often a zinc-rich epoxy, that offers cathodic protection by sacrificial action. Zinc-rich primers contain metallic zinc particles, which corrode preferentially to the steel, providing galvanic protection even if the coating is breached.

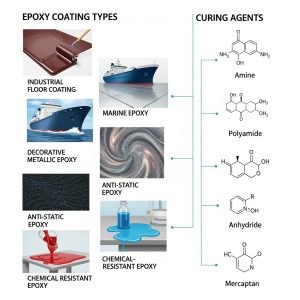

Following the primer, epoxy intermediate coats are applied to build barrier thickness. Epoxy coatings are thermosetting polymers known for their excellent adhesion, low permeability, and resistance to chemicals and seawater. For applications requiring exceptional impermeability such as splash zones and tidal interfaces, glass flake epoxy systems are often selected. These coatings embed micrometer-scale glass flakes within the matrix, creating a tortuous path that impedes moisture and ion penetration.

Anti-corrosion paint for ships is crucial in areas like ballast tanks, void spaces, bilges, and underwater hulls. The effectiveness of these coatings is directly influenced by surface preparation, environmental conditions during application, and film thickness control.

- Zinc-Rich Primers: These primers contain a high concentration of zinc dust, which provides sacrificial protection to steel substrates. When the steel is exposed, the zinc corrodes preferentially, protecting the underlying metal.

- Epoxy Coatings: Epoxies offer excellent adhesion, chemical resistance, and barrier properties. They are widely used as intermediate coats in multi-layer marine systems, particularly in ballast tanks and cargo holds.

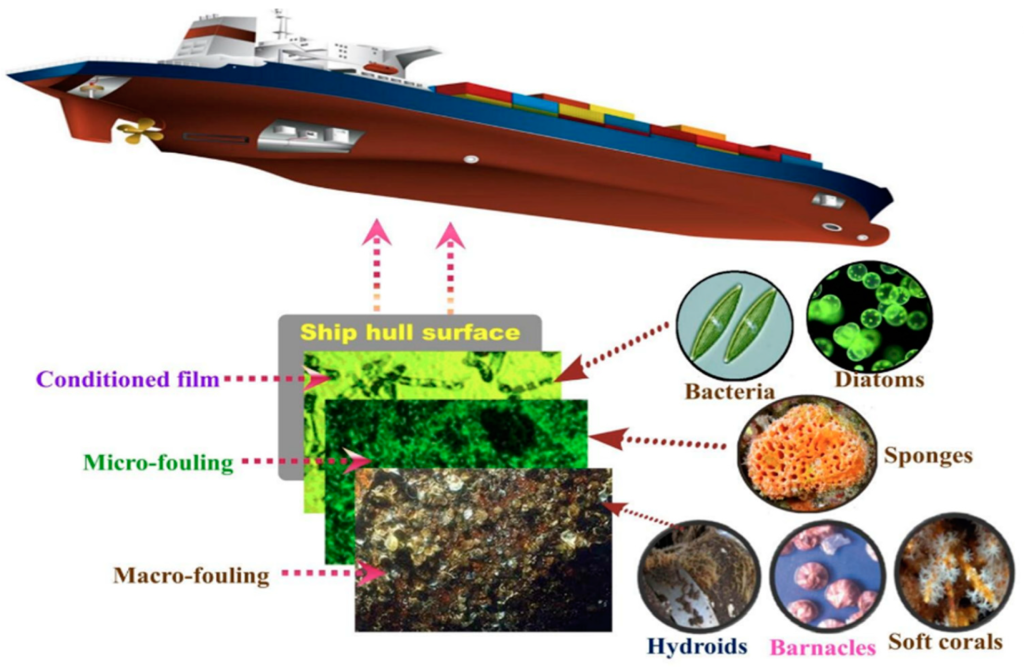

Antifouling Paints

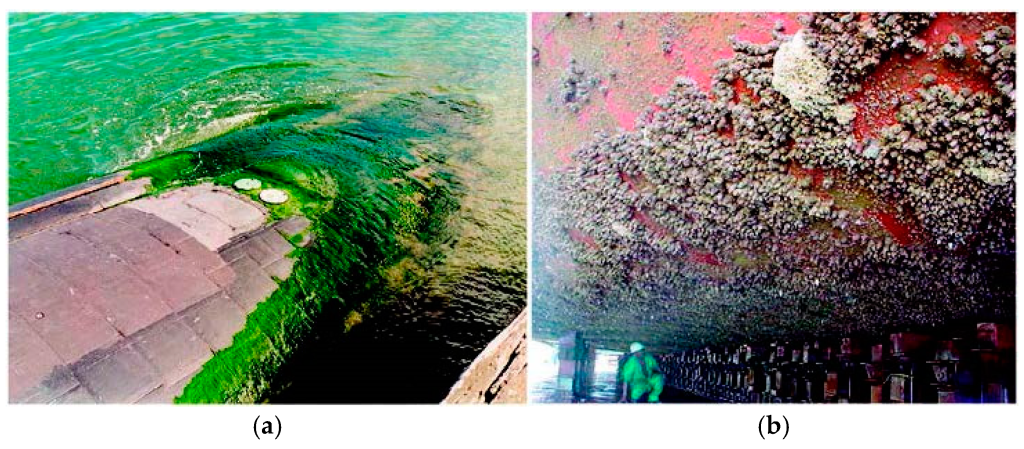

Marine biofouling, the accumulation of barnacles, algae, mussels, and slime on submerged surfaces adversely affects vessel hydrodynamics, increases fuel consumption, and leads to higher greenhouse gas emissions. Antifouling coatings are a subcategory of marine protective paint systems designed to mitigate this issue by preventing the attachment of these organisms.

Modern antifouling coatings are formulated as self-polishing copolymers (SPCs) or controlled depletion polymers (CDPs). SPCs undergo a chemical hydrolysis reaction in seawater, which causes the outer surface to erode at a predictable rate. This controlled polishing action continually exposes fresh biocide layers, ensuring consistent fouling protection throughout the coating’s service life. Common biocides include cuprous oxide, zinc pyrithione etc. These are environmentally friendly alternatives designed to meet regional biocide regulations, such as those imposed under the EU Biocidal Products Regulation (BPR).

CDPs, on the other hand, rely on the gradual leaching of biocides from a non-polishing matrix. While simpler and cheaper, CDPs are less durable and may not offer the same longevity as SPC systems. Antifouling marine coatings are essential for ship hull protection, particularly in warm, nutrient-rich waters where fouling rates are highest.

- Self-Polishing Copolymers (SPCs): These antifouling systems gradually erode in water, continuously exposing fresh biocide layers.

- Controlled Depletion Polymers (CDPs): Unlike SPCs, CDPs release biocides at a controlled rate but do not self-polish.

Foul-Release Coatings

Foul-release coatings are based on non-stick surface chemistry, typically involving silicone or fluoropolymer resins. These materials create a low surface energy interface, making it difficult for marine organisms to adhere.

When vessels are in motion, the hydrodynamic forces dislodge any biofilm or macrofouling organisms that may have attempted to settle. Foul-release coatings are ideal for high-speed vessels or those with regular operating cycles, as their effectiveness diminishes during prolonged static immersion.

Although initially more expensive than conventional antifouling systems, foul-release coatings offer extended drydock intervals and are often favored in regions where biocidal paints face regulatory restrictions. Their application aligns with sustainable shipping initiatives and can significantly contribute to fuel efficiency when combined with hull form optimization.

Topcoats

Topcoats provide the final aesthetic and protective layer in a marine coating system. They offer resistance to UV radiation, weathering, and mechanical damage. Topcoats serve as the outermost layer in a marine protective paint system, providing UV resistance, weathering protection, and color retention. These coatings also play an aesthetic role, offering a professional appearance while protecting the structural coatings beneath.

The most commonly used topcoats are aliphatic polyurethanes, known for their high gloss, abrasion resistance, and chemical tolerance. In superstructure applications such as decks, navigation bridges, and topsides, topcoats shield the epoxy underlayers from UV degradation, which can lead to chalking and loss of barrier performance.

Advanced systems may incorporate fluoropolymer modifications or ceramic additives to enhance dirt resistance and extend maintenance intervals. For critical applications, topcoats can also be designed with anti-slip properties or thermal reflectivity to meet operational safety and comfort standards.

Immersion Coatings and Tank Linings

Immersion service demands a special class of marine coatings formulated to resist continuous exposure to seawater, fuels, chemicals, or potable water. These are used in ballast tanks, fuel storage compartments, freshwater tanks, and bilges.

Epoxy novolac resins are commonly used in chemical-resistant linings, offering superior crosslink density and reduced solvent permeability. Potable water tank coatings, on the other hand, must comply with NSF/ANSI Standard 61 or similar standards and are free of leachable contaminants.

In ballast tanks, which are subject to cyclic wet-dry conditions, high-build epoxy systems that meet IMO PSPC (Performance Standard for Protective Coatings) are mandatory. These coatings must pass rigorous pre-qualification tests such as salt spray resistance, cathodic disbondment, and condensation chamber exposure.

Key Challenges in Marine Environments

The effectiveness and longevity of any marine protective paint system are determined not only by the coating formulation but also by the specific environmental challenges the asset faces throughout its service life. Marine environments are uniquely aggressive, characterized by constant exposure to water, salts, fluctuating temperatures, and mechanical stresses. The performance and durability of marine coatings are intrinsically linked to the environmental conditions they are exposed to.

Unlike terrestrial environments, marine structures face multiple degradation mechanisms that operate simultaneously. Each of these presents unique threats to both the substrate and the coating system. Understanding these environmental stressors is essential for selecting and applying the most suitable marine protective paint system, particularly when long-term asset protection, regulatory compliance, and lifecycle cost control are at stake.

Immersion Zone Exposure

The immersion zone represents the portion of a marine structure that remains continuously submerged in seawater. This zone is subjected to constant hydrostatic pressure, dissolved oxygen, chloride ions, temperature gradients, and biological activity, all of which accelerate corrosion processes. In carbon steel, for example, the presence of oxygen and chlorides enables the formation of iron oxides, which can spall off and expose fresh metal, continuing the cycle.

The prolonged exposure to water also introduces the risk of coating underfilm corrosion due to micro-permeation of moisture. This can be exacerbated if the coating has pinholes, poor adhesion, or improper surface preparation. Additionally, marine organisms such as sulfate-reducing bacteria (SRB) can initiate microbiologically influenced corrosion (MIC), especially in ballast tanks and offshore pilings.

To withstand these conditions, immersion coatings typically glass flake epoxies, novolac epoxies, or high-solids phenolics are formulated with low water vapor transmission rates (WVTR) and excellent cathodic disbondment resistance. In cathodically protected systems, the coating must also be electrically compatible to avoid premature degradation.

Ultraviolet (UV) Degradation

UV radiation is a primary cause of degradation for coatings exposed to the atmosphere, especially in above-waterline structures such as topsides, decks, navigation bridges, and cargo hatch covers. Prolonged UV exposure breaks down polymer chains in the binder matrix, causing chalking, color fading, loss of gloss, and ultimately erosion of the protective film.

This degradation is especially critical for epoxy coatings, which are highly susceptible to photodegradation. As such, they must always be overcoated with UV-resistant topcoats, typically aliphatic polyurethanes or fluoropolymers, to preserve both aesthetics and functional performance. In high-sunlight regions such as equatorial routes, UV exposure accelerates these effects, requiring more frequent inspections and recoating intervals if unsuitable materials are used.

Additionally, UV damage may lead to microcracking, which allows ingress of moisture and oxygen, promoting corrosion of the substrate beneath seemingly intact coatings. For this reason, UV stability testing, such as QUV accelerated weathering, is often performed to evaluate coating resilience.

Mechanical Abrasion of Marine Protective Coatings

Marine environments present numerous sources of mechanical abrasion that can wear down or remove protective coatings. These include:

- Contact with mooring lines, fenders, and docking equipment

- Hull cleaning operations (both manual and robotic)

- Scour by suspended particulates in harbor or river water

- Crew and cargo handling traffic on decks

- Impact from floating debris or small craft

Abrasion leads to loss of dry film thickness (DFT) and the creation of bare spots or stress concentrators that may lead to coating delamination. In splash and tidal zones, where wave action is intense and intermittent drying occurs, this abrasion is often paired with salt crystallization, which can create additional mechanical stresses on the coating.

Want to delve deeper into the concept of Dry Film Thickness? Check out our blog – Coating Dry Film Thickness (DFT) Measurements & Acceptance Criteria – FROSIO

To combat abrasion, coatings are often modified with ceramic beads, alumina fillers, or glass flake reinforcements, which increase hardness and enhance wear resistance. Specialized epoxy and polyurethane systems designed for abrasion-prone areas must also retain flexibility to accommodate dynamic loading.

Chemical Attack

Chemical exposure in marine settings comes from both external and internal sources. Ships and offshore structures regularly come into contact with:

- Hydrocarbons (fuels, oils, lubricants)

- Cleaning agents (alkaline or acidic)

- Ballast water treatment chemicals (biocides, neutralizers)

- Cargo chemicals (e.g., acids, solvents, alkalis)

- Environmental contaminants (industrial effluents, acidic rain)

Chemical attack can degrade coatings through swelling, softening, blistering, or underfilm corrosion. The degree of degradation depends on the chemical concentration, temperature, exposure time, and coating resistance.

For tank linings and chemical storage areas, coatings must exhibit excellent chemical impermeability, crosslink density, and solvent resistance. Systems such as epoxy novolac, vinyl ester, or phenolic resins are selected based on detailed chemical resistance charts and must be applied at verified film builds. Coating manufacturers often require immersion testing (per ASTM D1308 or ISO 2812) to validate suitability for specific cargos.

Ice Impact and Arctic Exposure

With the increase in Arctic shipping lanes and polar operations, marine coatings now face unique challenges in ice-prone regions. Ice imposes both abrasive and impact forces on vessel hulls and offshore structures, particularly in waterline and forward sections. These forces can:

- Cause coating cracking or spalling

- Promote disbondment at edges or weld seams

- Accelerate corrosion by creating ingress pathways for water and oxygen

To resist such conditions, ice-class marine coatings are formulated to maintain flexibility and adhesion at sub-zero temperatures. These coatings undergo specialized low-temperature testing such as the Charpy impact test, Mandrel bend test at –50°C, and ice abrasion resistance tests. They are designed to remain functional even under dynamic ice loadings and must often meet approval by classification societies (DNV, ABS, Lloyd’s Register) and compliance with the Polar Code.

Furthermore, coatings for polar environments often integrate elastomeric binders or polyurethane hybrids to tolerate rapid thermal cycling and minimize brittleness.

Coating Technologies and Application Methods in Marine Environments

In marine environments, the effectiveness of a coating system hinges not only on the formulation of the protective paint but also on the surface preparation, system design, and application techniques used. Below is an in-depth look at the critical elements of marine coating technologies and methods.

Surface Preparation Standards for Marine Coatings

Surface preparation is the most crucial determinant of coating adhesion and service life. Inadequate surface cleaning or profiling can lead to premature coating failure, blistering, and disbondment. The standardization of surface preparation is governed by internationally recognized codes and technical practices.

SSPC/NACE and ISO Standards

- SSPC-SP10 / NACE No. 2 (Near-White Metal Blast Cleaning) is the most widely used standard in marine and offshore applications. It requires the removal of all rust, mill scale, and old coatings, leaving only slight shadows or discoloration.

- SSPC-SP5 / NACE No. 1 (White Metal Blast Cleaning) is used when the highest level of cleanliness is required, such as for tank linings or splash zones.

- ISO 8501-1 provides a visual reference for the degree of cleaning, ranging from rust grade A (bare steel) to D (heavily rusted), and surface cleanliness grades Sa 1 to Sa 3.

- ISO 8503-1 and ASTM D4417 are used to quantify surface profile (roughness), which ensures mechanical anchorage of the coating. Profiles typically range between 50 to 100 microns for marine coatings.

- ISO 8502-6 and 8502-9 govern the measurement of soluble salt contamination on steel, using the Bresle method. Surface salts such as chlorides must be reduced to below 20 µg/cm² to avoid osmotic blistering and underfilm corrosion.

Want to know more about the Bresle method? Check out our blog – The Role of Soluble Salts in Coating Failures: Mechanisms, Detection, and Industry Practices

Advanced techniques such as ultra-high pressure water jetting (UHPWJ) are increasingly used for environmentally sensitive locations, especially in repair yards and offshore platforms. UHPWJ effectively removes rust and chlorides without generating dust or embedding abrasive residues.

Marine Coatings System Design

A complete marine coating system typically comprises three layers:

- Primer – Provides adhesion and often sacrificial protection. Zinc-rich primers offer cathodic protection and are used widely for steel substrates.

- Intermediate Coat – Adds film build and barrier properties. Usually an epoxy or glass flake epoxy to resist water permeation and mechanical wear.

- Topcoat – Offers resistance to UV radiation, weathering, and surface erosion. Aliphatic polyurethanes are most common for their color retention and durability.

Each layer serves a specific function and is selected based on location (e.g., immersion zone, splash zone, atmospheric zone), environmental aggressiveness (ISO 12944 C5-M, CX), and coating specification.

For example, in ballast tanks:

- Zinc silicate primer → excellent adhesion and cathodic protection

- Epoxy intermediate layer → high DFT (Dry Film Thickness) and water resistance

- No topcoat (as aesthetics are not a priority, unless dual-use)

For external hulls:

- Zinc-rich epoxy → corrosion inhibition

- Glass flake epoxy → abrasion and water resistance

- Foul-release or antifouling topcoat → biofouling control

Compatibility between coating layers is essential. Manufacturers typically publish Product Data Sheets (PDS) and System Compatibility Charts to guide proper selection and overcoating intervals.

Best Practices for Selection and Maintenance of Marine Coatings

A marine protective coating system is a capital investment that protects high-value assets against corrosion, fouling, and mechanical degradation. To maximize return on investment and ensure regulatory compliance, asset owners and engineers must adopt best practices in both coating selection and ongoing maintenance. These practices should be guided by site-specific conditions, regulatory frameworks, operational priorities, and lifecycle cost considerations.

Marine Coatings Selection Guidelines

The selection of a marine protective paint system should begin with a comprehensive evaluation of environmental exposures, material compatibility, and performance requirements. Key factors include:

- Environmental Classification: Use ISO 12944 or NORSOK M-501 to identify the severity of exposure, C3 for urban atmospheric zones, C5-M/CX for aggressive marine and offshore environments.

- Service Conditions: Consider immersion, tidal zones, UV exposure, temperature fluctuations, and abrasion. Select high-performance epoxies, glass flake barriers, or foul-release systems as appropriate.

- Substrate Type: Coating adhesion and performance vary by substrate (e.g., carbon steel, stainless steel, aluminum). For instance, zinc-rich primers may not be suitable for stainless steel.

- Operational Requirements: Include repairability, touch-up strategies, dry-to-handle time, and overcoating flexibility.

- Compliance Standards: Ensure coatings meet standards such as IMO PSPC, NACE SP0108, REACH, or NSF 61 for potable water tanks.

A well-documented Coating Specification should define surface preparation standards, DFT requirements, number of coats, and QA/QC parameters. Engaging with certified coating manufacturers and applicators ensures compatibility and support.

Maintenance Planning and Inspection

Maintenance planning should be predictive, not reactive. Regular inspections allow for early detection of coating deterioration, enabling targeted touch-ups rather than costly total recoats.

- Inspection Intervals: Follow class society recommendations or internal asset management protocols. Immersion areas typically require inspection every 2–3 years; atmospheric zones every 4–6 years.

- Inspection Tools: Use ultrasonic thickness gauges, adhesion testers, and holiday detectors to assess performance. Drone-based visual inspections are emerging for difficult-access zones.

- Failure Analysis: When coating failure is observed (blistering, delamination, rust-back), conduct a root cause analysis. Common culprits include improper surface prep, application errors, incompatible overcoats, or UV/photo-degradation.

- Record Keeping: Maintain coating data sheets, batch numbers, inspection logs, and touch-up history in a centralized coating technical file. This is critical for auditing, warranty claims, and long-term lifecycle analysis.

Life Cycle Cost Evaluation

Initial coating costs may represent only 10–20% of the total lifecycle cost. The majority of expenses arise from maintenance, unplanned dry docking, downtime, and corrosion-induced repairs. A life cycle cost analysis (LCCA)should incorporate:

- Coating system longevity

- Inspection and recoating frequency

- Application cost per m²

- Downtime and cleaning intervals

- Fuel savings from smooth hull performance (in case of antifouling systems)

By prioritizing coatings with longer maintenance intervals and higher resistance properties, asset owners can optimize operating costs and reduce environmental impact.

Conclusion

Marine protective coatings are more than a protective layer, they are a strategic component of asset management, regulatory compliance, and environmental sustainability. In environments dominated by salt, humidity, UV radiation, and biological activity, high-performance coating systems preserve the structural integrity of ships, platforms, and port infrastructure.

From the selection of anti-corrosion paint for ships and marine protective paint to the execution of surface preparation and controlled application, each step influences coating performance and service life. By adhering to international standards, incorporating advanced coating technologies, and implementing proactive maintenance programs, marine stakeholders can significantly extend asset lifespans and reduce lifecycle costs.

In a time when sustainability, cost-efficiency, and safety are more interlinked than ever, coatings are not merely protective, they are strategic.

Blog Prepared by:

R. Venkatesan

Protective Coating Specialist

Senior Training Instructor for FROSIO / ICorr

+91-9176618930 / info@htscoatings.in / info@frosiotraining.com

One Response

Hi,