Introduction to Surface Profile

Importance of Surface Profile in Adhesion, Friction, and Wear Resistance

Major Surface Profile Parameters

Measurement Standards for Surface Profile

Surface Profile Standards and Specifications

Surface Profile Measurement Techniques

Challenges in Surface Profile Measurement

Introduction to Surface Profile

Surface profile, the three-dimensional topography of a material’s surface — directly influences critical performance attributes such as coating adhesion, friction behavior, corrosion resistance, and overall durability. Whether preparing steel substrates for protective coatings or optimizing wafer surfaces in semiconductor fabrication, precise control and measurement of surface profile parameters are essential for ensuring product reliability and operational longevity. This article explores the fundamentals of surface profile and delves into key parameters and surface profile measurement techniques.

What is Surface Profile?

Surface profile refers to the microstructural topography of a material’s surface, characterized by the peaks and valleys formed through mechanical or chemical processes. At the microscale, the surface of a material is rarely perfectly smooth; instead, it comprises a complex landscape that can significantly influence the material’s interaction with coatings, adhesives, and other contacting surfaces. This microscale structure is quantified using various parameters that provide insight into the surface’s roughness, texture, and contour. Modern surface engineering relies heavily on precisely characterizing and controlling surface profiles to optimize performance, longevity, and reliability.

Importance of Surface Profile in Adhesion, Friction, and Wear Resistance

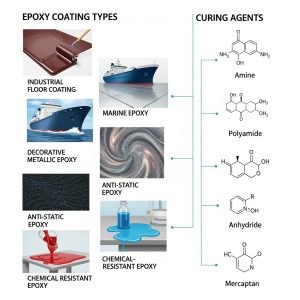

The surface profile plays a vital role in dictating adhesion properties, frictional behavior, and wear resistance of coatings and bonded materials. In coating applications, an appropriately roughened surface increases the surface area available for mechanical interlocking, thereby enhancing the adhesive bond strength between the substrate and the coating. For example, abrasive blasting of steel before applying epoxy coatings is a well-established practice guided by standards such as SSPC-SP 5/NACE No. 1 (White Metal Blast Cleaning) and ISO 8501-1.

Want to know more about adhesion between coating and substrate? Check out our blog on COATING’S ADHESION & COHESION

In frictional systems, surface profile affects the coefficient of friction by altering the real area of contact. A moderately rough surface may enhance friction, providing better traction, while overly rough or overly smooth surfaces can lead to undesirable slipping or wear. Similarly, wear resistance is intimately linked to surface topography. Failure to adequately prepare and characterize the surface can result in coating delamination, underfilm corrosion, and mechanical failure, especially in aggressive service environments such as marine, chemical processing, and high-temperature applications.

Major Surface Profile Parameters

Quantifying surface profile requires precise measurement techniques, typically using contact stylus profilometers, optical profilometry, or advanced 3D scanning systems. Several key parameters are routinely employed in surface profile characterization. Let’s look into each one of them in detail:

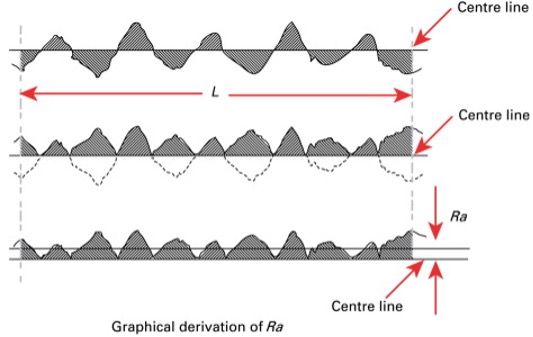

Ra (Arithmetic Average Roughness)

Ra, the arithmetic average of the absolute values of the surface height deviations measured from the mean line over a specified evaluation length, is the most widely used roughness parameter. It is defined mathematically as:

Ra = (1/L) * ∫|y(x)|dx

where y(x) is the surface profile, L is the evaluation length, and the integral is computed over the entire evaluation length. Ra is typically expressed in micrometers (µm) or nanometers (nm).

Ra provides a general sense of the surface roughness but lacks sensitivity to extreme peaks or valleys. In industries such as protective coatings and surface finishing, standards like ISO 4287 and ASTM D7127 specify Ra limits to ensure adequate adhesion and appearance.

Rz (Average Maximum Height of the Profile)

Rz measures the mean vertical distance between the five highest peaks and the five deepest valleys within the evaluation length. Unlike Ra, which averages the surface, Rz emphasizes peak-to-valley extremes, providing more sensitivity to the surface’s texture.

The formula for Rz is:

Rz = (1/N) * Σ(Pi – Vi)

where N is the number of sampling lengths, Pi is the highest peak within the ith sampling length, and Vi is the lowest valley within the ith sampling length.

Rz is particularly useful in specifying surface conditions for sealing surfaces, corrosion protection, and paint adhesion, where surface texture must be sufficiently aggressive without being detrimental.

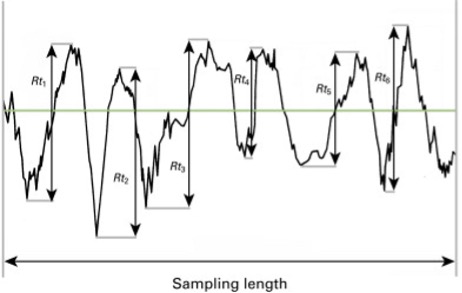

Rt (Total Height of the Profile)

Rt, or the total height of the profile, is the vertical distance between the highest peak and the deepest valley across the entire sampling length. It represents the extreme vertical range of the surface profile and can highlight defects or inconsistencies that average measurements such as Ra might obscure.

Rt is critical in precision engineering sectors, such as aerospace, where a single deep scratch or peak can compromise component functionality or fatigue resistance.

Measurement Standards for Surface Profile

Precise surface profile characterization requires adherence to established standards to ensure repeatability and comparability across industries. Best practices dictate calibrating measurement instruments before use, selecting the correct measurement method (contact or non-contact), ensuring cleanliness of the surface, and applying statistical analyses where appropriate to account for variability across a substrate.

Surface Profile Standards and Specifications

The accurate assessment and control of surface profile are fundamental to ensuring the long-term performance of protective coatings and surface treatments. Several internationally recognized standards outline the procedures, measurement methods, and acceptable ranges for surface profile. These standards serve to harmonize surface preparation practices across industries, thereby ensuring consistency, reliability, and compliance with performance requirements.

ISO 8503 is one of the foremost standards governing surface roughness measurement on blast-cleaned steel substrates. It comprises several parts, notably ISO 8503-1, which details the methodology for comparator-based visual assessments, and ISO 8503-5, which describes the use of replica tape for surface profile measurement. These standards emphasize the importance of selecting appropriate surface profile comparators and measurement devices based on the intended service conditions of the coated structure.

ASTM D4417 is widely used, particularly in North America, for field measurement of surface profile on blast-cleaned steel. It provides three distinct methodologies: Method A (depth micrometer readings), Method B (replica tape), and Method C (surface profile comparator). Each method specifies procedural details to ensure repeatability and reproducibility, highlighting the necessity of proper calibration and measurement technique.

SSPC-SP 5 and SSPC-SP 10, developed by the Society for Protective Coatings (SSPC), establish surface preparation grades known as “White Metal Blast Cleaning” and “Near-White Metal Blast Cleaning,” respectively. Although these standards primarily focus on cleanliness levels, they implicitly link to surface profile quality by requiring surfaces to be free of contaminants and prepared to a degree that facilitates optimal coating adhesion. In many industrial specifications, the required surface profile is explicitly stated alongside the cleanliness standard to avoid ambiguity.

Collectively, these standards form the backbone of surface preparation protocols in industries ranging from oil and gas to aerospace. Adherence ensures that coatings perform as designed, reducing the risk of premature failure due to inadequate adhesion, underfilm corrosion, or mechanical damage.

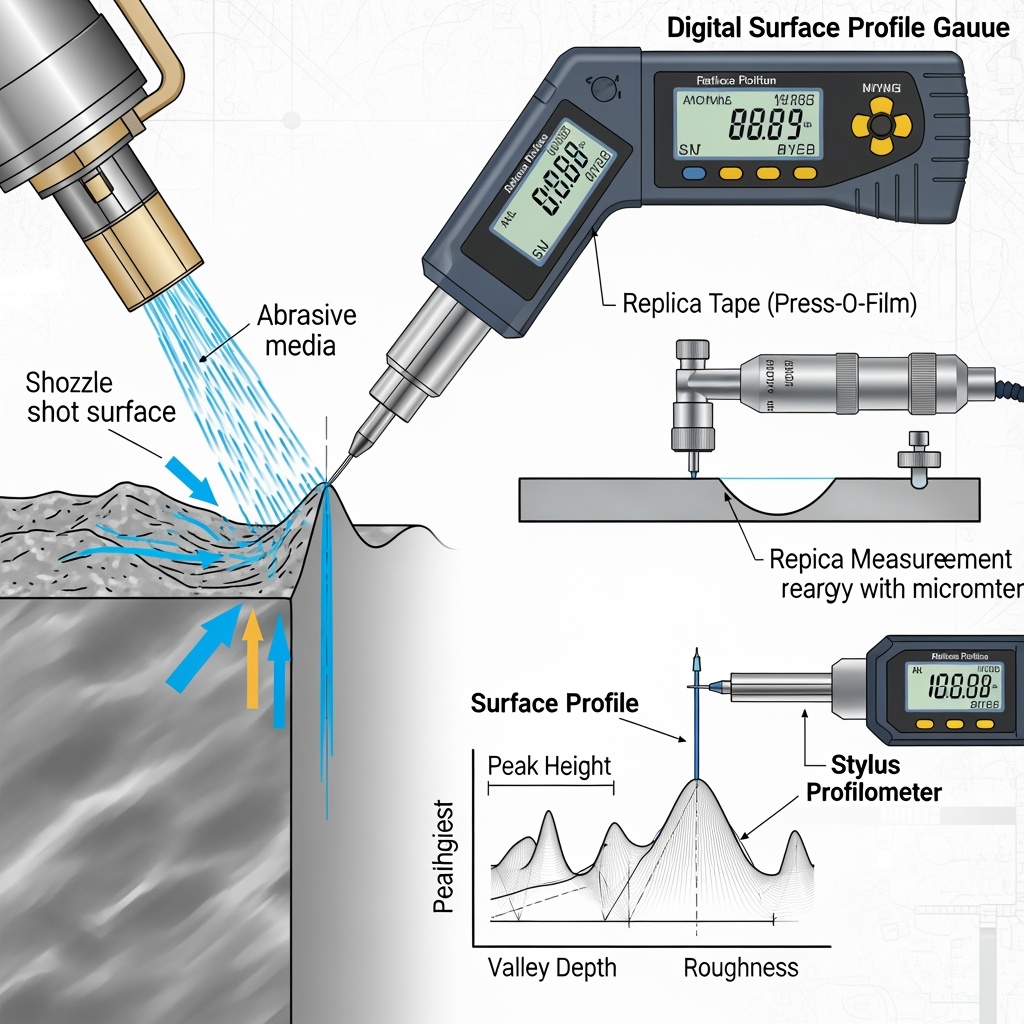

Surface Profile Measurement Techniques

Precise measurement of surface profile is crucial for verifying compliance with specification requirements and ensuring consistent surface quality. Various measurement techniques are available, each offering unique advantages, limitations, and preferred use cases.

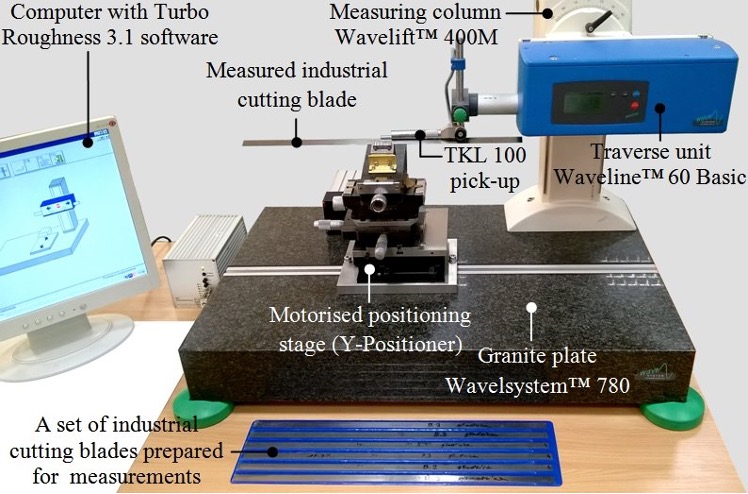

Stylus Profilometers

Stylus profilometry remains a gold standard for precise and repeatable surface profile measurements. The stylus device physically traverses the surface with a diamond-tipped probe, recording vertical displacement to generate a two-dimensional profile. Measurements such as Ra (arithmetic average roughness), Rz (average maximum height), and Rt (total height) can be directly calculated from the data.

The advantages of stylus profilometers include high accuracy, wide dynamic range, and direct traceability to established roughness standards like ISO 4287. However, stylus profilometers are sensitive to surface contamination, and the probe’s finite radius can miss the smallest valleys or underestimate sharp peaks. Additionally, the mechanical contact between the stylus and the surface may risk damaging delicate substrates, making this method less suitable for very soft or highly engineered surfaces.

Typical applications include quality control laboratories, verification of critical engineering surfaces, and R&D activities where detailed surface characterization is required.

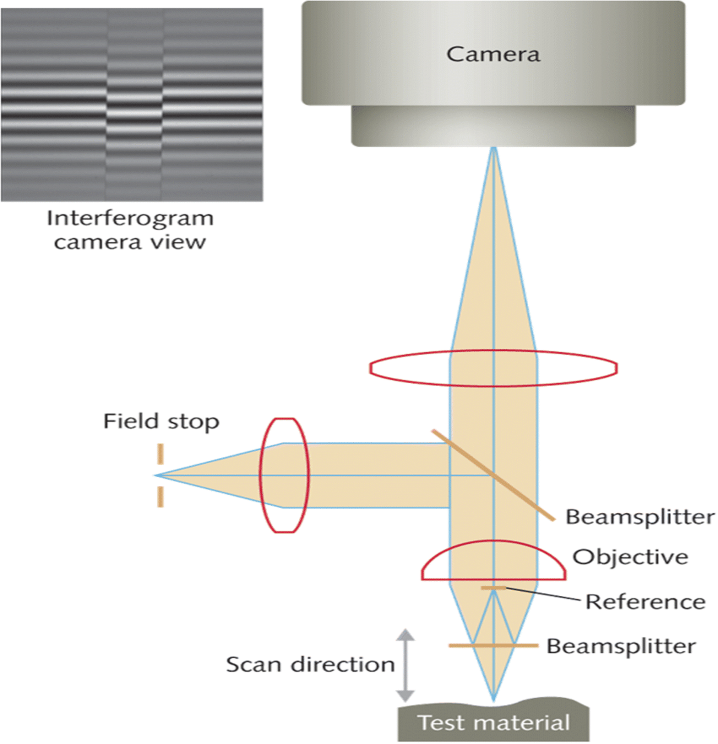

Optical Profilometers

Optical profilometry provides non-contact measurement of surface roughness using techniques such as white light interferometry (WLI) or confocal microscopy. By analyzing the interference patterns or focal variations of reflected light, these instruments can generate highly detailed three-dimensional topographic maps.

The principal advantages of optical profilometers include their non-destructive nature, high resolution (down to nanometer scales), and capability for large-area scans. Optical systems eliminate the risk of physically damaging the sample, making them ideal for soft materials, coatings, and precision-engineered surfaces.

Nevertheless, optical profilometers have limitations, particularly when measuring highly reflective, transparent, or very rough surfaces where the light signal may become distorted. Instrument cost and complexity also restrict their widespread field use.

Common applications include advanced manufacturing industries such as semiconductor fabrication, medical device engineering, and aerospace component inspection, where stringent surface requirements are enforced.

Atomic Force Microscopy (AFM)

Atomic Force Microscopy is a highly sophisticated technique that employs a sharp nanoscale probe to scan the surface at extremely high resolution. Unlike traditional profilometers, AFM measures forces between the probe and the surface atoms, enabling characterization of surface features at the nanometer and even sub-nanometer scale.

AFM offers unparalleled surface resolution and is capable of providing additional information about material properties such as adhesion, stiffness, and electrical conductivity. Its chief advantage lies in its applicability to both smooth and highly textured surfaces without requiring special sample preparation.

However, AFM has significant limitations in the context of industrial surface profile measurement. It is time-consuming, limited to small scanning areas (typically a few microns to millimeters), and requires controlled environments to minimize vibrations and thermal drift.

AFM is best suited for research and development settings where nanoscale surface characteristics influence material performance, such as in nanocoatings, biomaterials, and precision optics.

Replica Tape Method

The replica tape method remains one of the most practical and field-deployable techniques for surface profile measurement, especially on large structures and in harsh environments. It involves pressing a compressible foam tape against the prepared surface to create a negative impression. The thickness of the tape’s compressed profile is then measured using a micrometer, yielding an estimation of the surface peak-to-valley height.

Replica tape’s advantages include ease of use, portability, cost-effectiveness, and minimal operator training requirements. It is particularly beneficial for verifying surface preparation in the field, such as on bridges, pipelines, storage tanks, and offshore platforms.

Nonetheless, replica tape only measures the peak-to-valley height (similar to Rz or Rt) and does not provide detailed information about surface waviness or microtexture. Moreover, correct tape handling, proper application pressure, and consistent measurement technique are critical for achieving accurate and reproducible results, as specified in NACE SP0287 and ASTM D4417 Method B.

Field inspection, quality control during blasting operations, and maintenance audits are among the most common applications of replica tape.

Industrial Applications

Surface profile control is vital across a range of industries where adhesion, functional performance, and surface integrity are critical. In protective coatings for steel structures, the surface profile directly impacts the mechanical anchorage between the substrate and the coating system. Standards such as SSPC-SP10/NACE No. 2 specify a near-white metal blast cleaning with a surface profile depth suitable for heavy-duty coatings. For marine coatings, for example, a profile of 50–75 micrometers (2–3 mils) is often mandated to achieve optimal adhesion under aggressive saltwater exposure, as outlined in ISO 8501-1 and relevant shipbuilding specifications.

In printed circuit board (PCB) manufacturing, controlled surface profiles are essential during surface finishing processes such as electroless nickel/immersion gold (ENIG) coating. Excessive roughness can induce solderability issues, while insufficient roughness can impair layer adhesion. IPC standards such as IPC-4552A guide surface preparation, emphasizing microscale roughness thresholds to ensure reliable performance of multilayer circuits.

The semiconductor manufacturing sector demands the most stringent surface profile control, often at the sub-nanometer scale. During wafer fabrication, atomic layer deposition (ALD) and chemical mechanical polishing (CMP) steps require ultra-smooth surfaces with Ra values below 0.2 nm. Surface roughness must be minimized to ensure the integrity of photolithographic patterning and prevent device failure. Standards such as SEMI E49 and ASTM F1377 specify measurement procedures for such high-precision requirements.

Want to know more about Protective Coatings? Check out our post – Protective Coatings

Industrial Importance of Surface Profile Control

Control over surface profile is indispensable across a wide range of industries due to its direct impact on coating adhesion, corrosion resistance, frictional behavior, fatigue life, and aesthetic quality. In protective coatings applications, inadequate surface profile is a frequent cause of premature coating failure. A surface that is too smooth can inhibit mechanical anchoring, while excessively rough surfaces can create stress concentrations that propagate coating defects.

For instance, offshore oil platforms require meticulously prepared surfaces conforming to ISO 8503 and ASTM D4417 to withstand extreme marine environments. Similarly, in aerospace, components often demand highly controlled surface profiles to balance aerodynamic efficiency with fatigue resistance. Even in medical device manufacturing, surface roughness is engineered to optimize biocompatibility, osseointegration, or antimicrobial properties.

Industry best practices dictate that surface profile measurements should be taken not only after initial surface preparation but also at critical stages during maintenance cycles. This ensures that any degradation or deviation from the specified surface condition is promptly identified and corrected, thereby safeguarding operational integrity and extending service life.

Quality control professionals, surface engineers, and coating inspectors must be intimately familiar with the applicable standards, measurement techniques, and interpretation of results to effectively manage surface quality. They must also recognize the limitations inherent to each method and select the most appropriate technique based on material characteristics, environmental conditions, and service requirements.

Ultimately, surface profile measurement and control are not isolated quality tasks but integral parts of a comprehensive surface engineering strategy that underpins structural reliability, performance optimization, and cost-effective asset management across industrial sectors.

Challenges in Surface Profile Measurement

Accurately capturing surface profiles is vital across multiple fields such as quality assurance, tribology, and manufacturing process optimization. Nonetheless, achieving consistent and precise measurements is often complicated by a range of factors, including environmental influences, instrument configurations, and the inherent properties of the surfaces under evaluation. Let’s explore these factors in detail:

Environmental conditions are a significant contributor to variations in surface profile measurements. Variables like temperature, humidity, and atmospheric pressure can impact both the measuring equipment and the surface itself, leading to potential measurement errors. For example, temperature changes may cause the material to expand or contract, thereby altering the surface parameters recorded. Similarly, elevated humidity can result in condensation, which may disrupt both contact-based and optical measurement methods.

Instrument configuration is another critical element affecting measurement fidelity. In contact techniques, parameters such as stylus tip radius, sampling length, and evaluation length are influential. In non-contact methods, variables like the light source wavelength, angle of incidence, and numerical aperture play essential roles. Tailoring these settings to the specific application and surface type is necessary to achieve accurate results.

Surface characteristics further complicate measurement efforts. Surfaces with pronounced roughness, steep gradients, or intricate geometries are particularly challenging and often necessitate specialized equipment or methodologies. Additionally, the presence of surface contamination or debris can significantly distort results, making surface cleanliness a vital prerequisite for obtaining dependable measurements.

How to Overcome Surface Profile Measurement Challenges?

Several methods can be implemented to enhance the accuracy and reliability of surface profile measurements, addressing common challenges through thorough preparation, instrument calibration, and adherence to recognized best practices in surface metrology.

An essential starting point is a deep understanding of both the measurement application and the surface characteristics. This insight enables the selection of the most suitable measurement techniques and equipment settings. For instance, choosing an appropriate stylus tip radius for contact-based measurements, or selecting the correct wavelength and angle for optical methods, helps reduce measurement errors.

Accurate calibration of instruments is fundamental to achieving precise results. Routine calibration ensures that equipment remains within its specified tolerance limits and enables reliable comparison of measurements taken at different times or with different instruments. Following strict calibration protocols and using certified reference standards greatly enhances the credibility of the measurement outcomes.

Managing environmental factors is also key to mitigating measurement errors. Maintaining stable conditions—specifically temperature, humidity, and air pressure—during measurements helps minimize environmental impacts. Conducting measurements within controlled environments, like climate-regulated metrology laboratories, further improves the precision of surface profile data.

Proper surface preparation is another critical factor. Surfaces must be thoroughly cleaned to remove dust, oils, or debris that could interfere with measurement accuracy. Techniques such as ultrasonic cleaning, solvent cleaning, or plasma cleaning can be employed to achieve a contaminant-free surface without damaging it or introducing artifacts.

Another effective strategy is utilizing multiple measurement methods. Integrating data from both contact and non-contact techniques—a process referred to as data fusion—can help detect and correct errors or artifacts, thereby enhancing the overall accuracy and reliability of the measurements.

Finally, consistently following established standards and guidelines, such as those issued by ISO, ASTM, and DIN, ensures that surface profile measurements are conducted uniformly. Compliance with these frameworks supports data comparability and strengthens the integrity of measurements across different industries and applications.

Future Trends

The future of surface profiling is increasingly oriented toward non-contact, high-precision, and data-rich methodologies. Non-contact optical methods, particularly white-light interferometry and confocal laser scanning microscopy, offer significant advantages over traditional tactile methods. These techniques provide full three-dimensional surface maps with high lateral and vertical resolution, minimizing risk of surface damage and operator influence. ISO 25178-6 outlines guidelines for areal (3D) surface texture measurement, which is rapidly gaining preference in industries requiring detailed topographical analysis.

Machine learning and artificial intelligence are beginning to revolutionize surface analysis. Algorithms trained on vast datasets of surface images and roughness measurements can predict surface parameters, classify surface conditions, and even recommend corrective actions. In quality control environments, integrating machine learning with optical profilometers can enable real-time, automated surface assessments, drastically reducing inspection times while enhancing reliability.

The evolution of standards is keeping pace with these technological advancements. ISO 21920, introduced as a replacement for ISO 4287 and ISO 4288, modernizes the definition of surface roughness parameters for both profile and areal measurements, better reflecting the capabilities of next-generation instrumentation.

Conclusion

In conclusion, surface profiling remains a cornerstone of material engineering, with accuracy and reliability paramount to ensuring optimal performance of coatings, mechanical components, and electronic devices. As measurement technology advances and standards evolve, surface engineers, quality control professionals, and coating inspectors must stay abreast of best practices and emerging tools to maintain excellence in surface characterization.

Blog Prepared By:

R. Venkatesan

Protective Coating Specialist

Senior Trainer / Instructor for FROSIO / ICorr

+91-9176618930 / info@htscoatings.in / info@frosiotraining.com